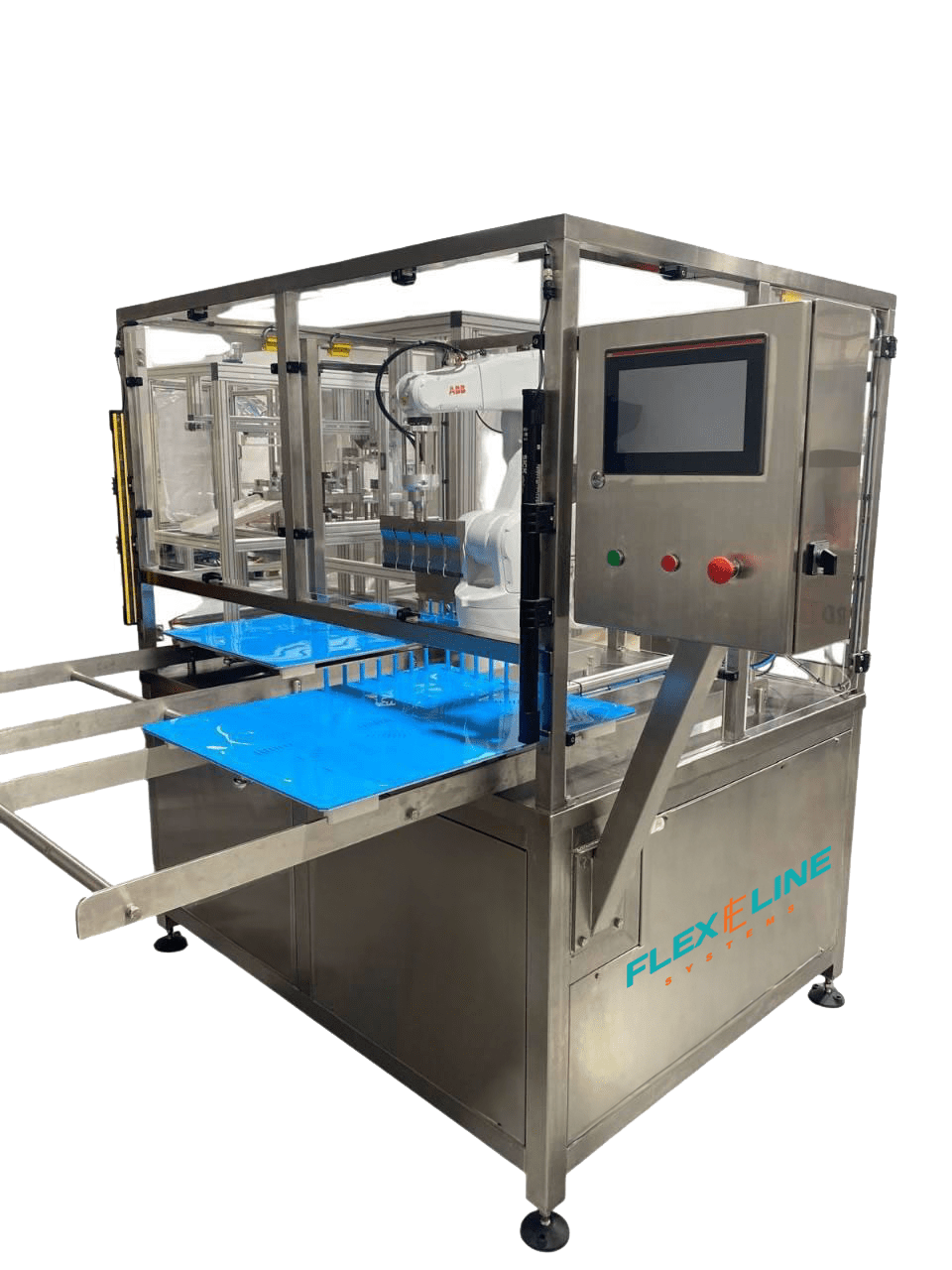

Robot equipped with an ultrasonic knife is a high-tech solution for automating the cutting of cakes, pastries, and other products that require high precision and flexibility in processing.

Key Features:

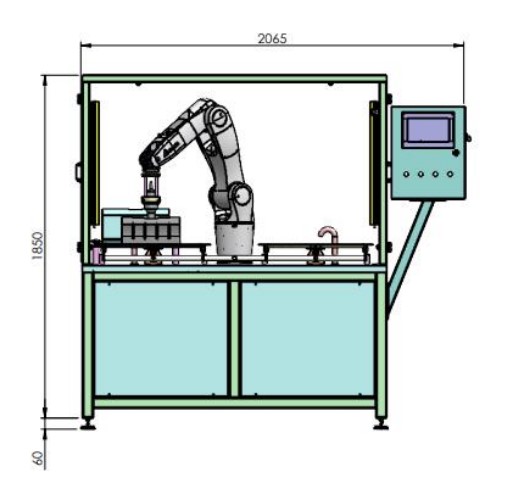

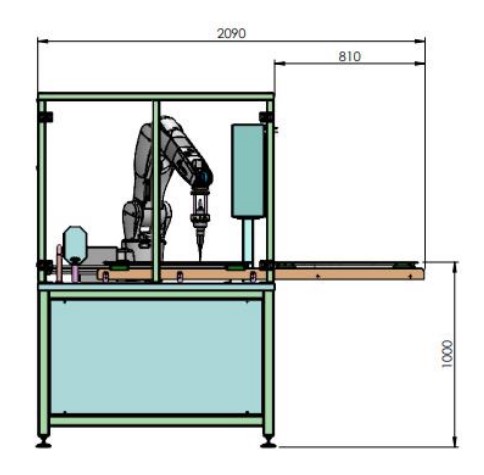

- A robotic manipulator with six degrees of freedom provides maximum flexibility in movement.

- Allows cutting products at various angles, along complex trajectories, and into unconventional shapes.

- Can handle products of different heights and shapes.

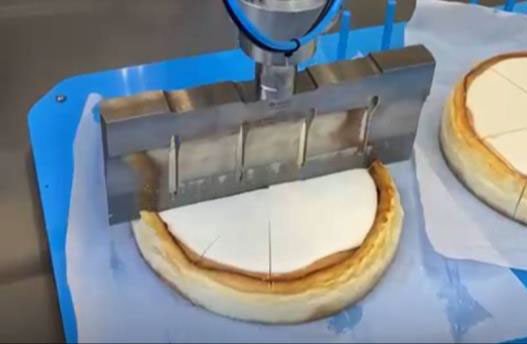

Ultrasonic knife:

- Equipped with a cutting blade vibrating at ultrasonic frequency (typically 20 to 40 kHz).

- Ensures clean cuts without sticking, even on products with soft or sticky textures (e.g., creams, glazes, mousses).

- Easily handles multi-layered and frozen products.

Programmable cutting:

- Supports various cutting patterns: squares, triangles.

- Easy to adjust parameters via software (e.g., the operator can set the number and size of portions).

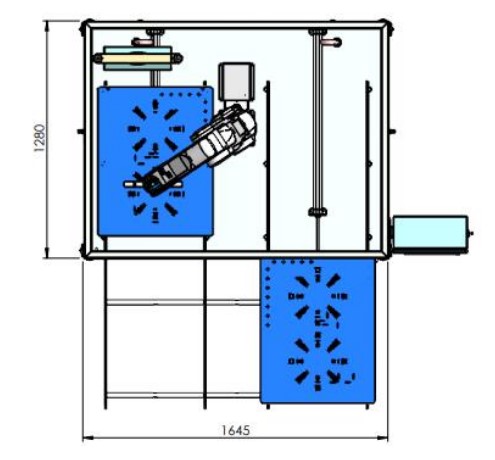

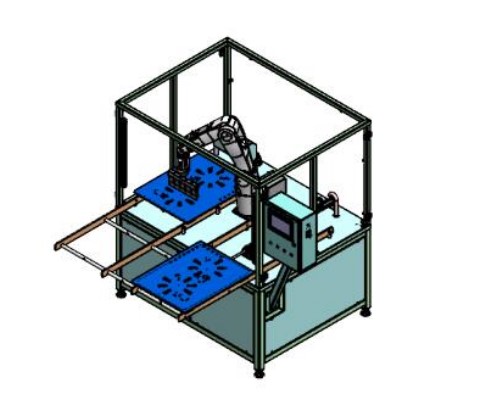

Working Principle:

- Products are placed in the working area manually, via with a positioning platform.

- The robot calculates the optimal cutting trajectory.

Robotic manipulator:

- The six-axis robotic manipulator moves the ultrasonic knife along the programmed trajectory.

Flexibility and versatility:

- Suitable for processing various products: cakes, rolls, cheesecakes, frozen desserts, pizzas, and even soft cheeses.

High precision:

- The six-axis design ensures millimeter-level accuracy when working with any product.

- Ultrasonic technology guarantees clean cuts without damaging textures.

Efficiency and productivity:

- Automation reduces processing time and minimizes human error.

- Capable of processing multiple products consecutively thanks to the manipulator’s speed.

Waste reduction:

- Precise cutting minimizes product loss.

Ease of integration:

- The robot can be easily incorporated into existing production lines.

- Simple programming

Applications:

- Confectionery production: Cutting cakes and pastries into predefined sizes.

- Bakeries: Cutting bread, pizzas, and other baked goods.

- Cheese production: Cutting soft or semi-hard cheeses.

This type of equipment is ideal for manufacturers requiring maximum flexibility and high-speed performance when working with a wide range of products.