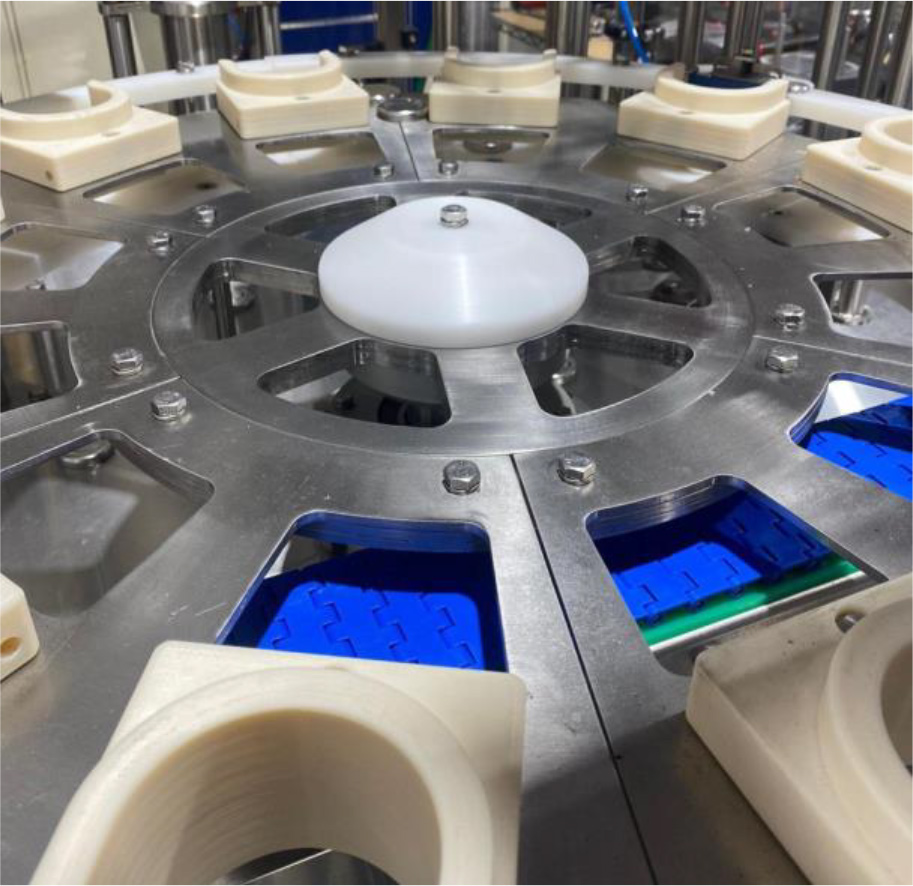

The rotary automatic filling and sealing machine is designed for dosing liquid or viscous products into containers, hermetically sealing them.The machine offers high performance, precise dosing, and reliable operation, making it ideal for use in the food, cosmetics, and chemical industries. It is suitable for handling various types of jars, bottles, and other containers.

Advantages

- Fully automated operation.

- High dosing accuracy and reliable sealing.

- Easy maintenance and adjustment.

- Compact size and sturdy design.

- Compliance with food and pharmaceutical industry standards