Modified Atmosphere Packaging (MAP) machine designed to extend the shelf life of perishable products by altering the atmosphere inside the packaging. These machine replace the normal air with a specific gas mixture, such as carbon dioxide, nitrogen, or oxygen, depending on the product being packaged. This process slows down the spoilage caused by microbial growth, oxidation, and moisture loss.

Gas Flushing:

The machine introduces a gas mixture into the packaging, replacing the oxygen that typically accelerates spoilage. The specific gas mixture depends on the type of product being packaged.

Sealing:

After the air has been replaced, the machine seals the package tightly, ensuring that the modified atmosphere remains intact throughout the product’s shelf life.

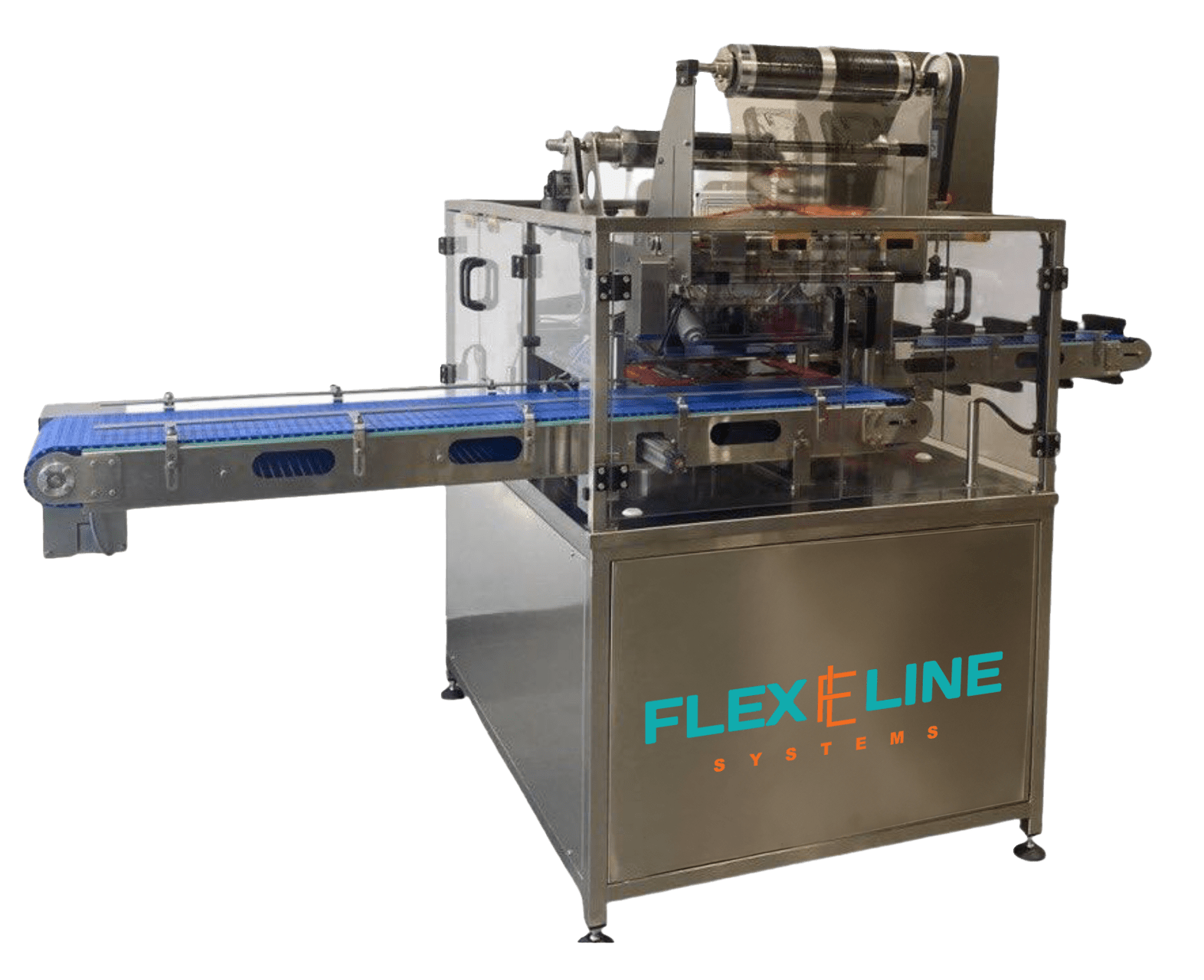

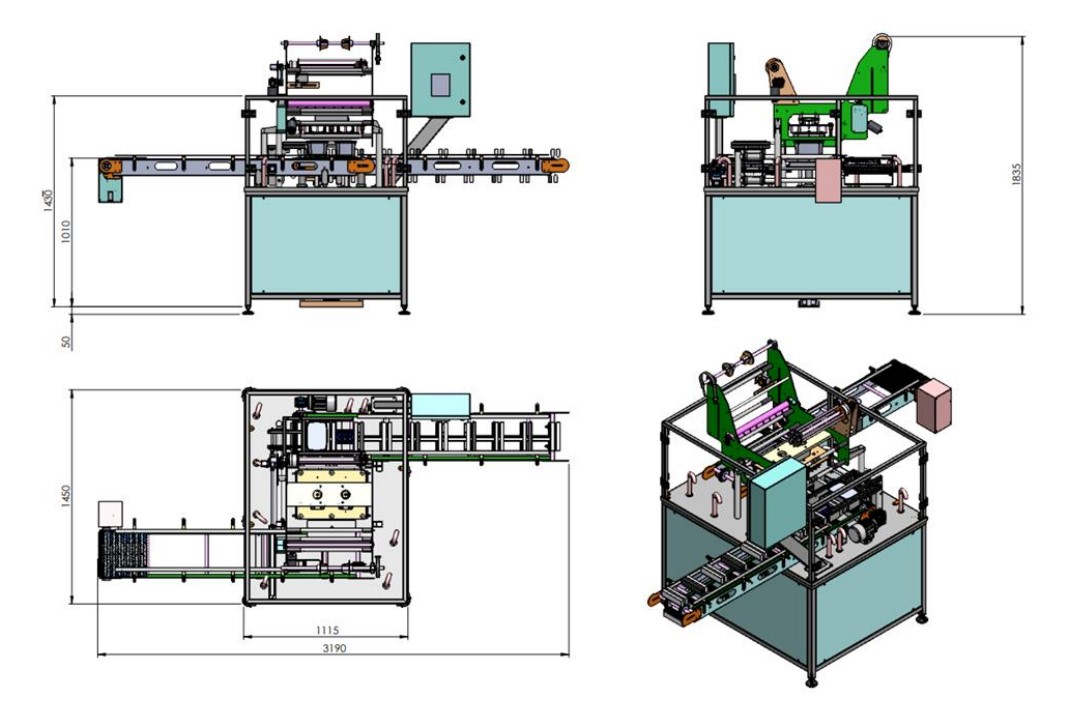

Product Handling:

Machine integrated with conveyors for handling products efficiently, making them suitable for high-volume production lines.

Customizability:

Machine can be tailored to suit different packaging materials and sizes.

Applications of MAP Packaging Machines:

- Fresh Meat and Poultry.

- Seafood.

- Cheese and Dairy Products.

- Baked Goods.

Fruits and Vegetables