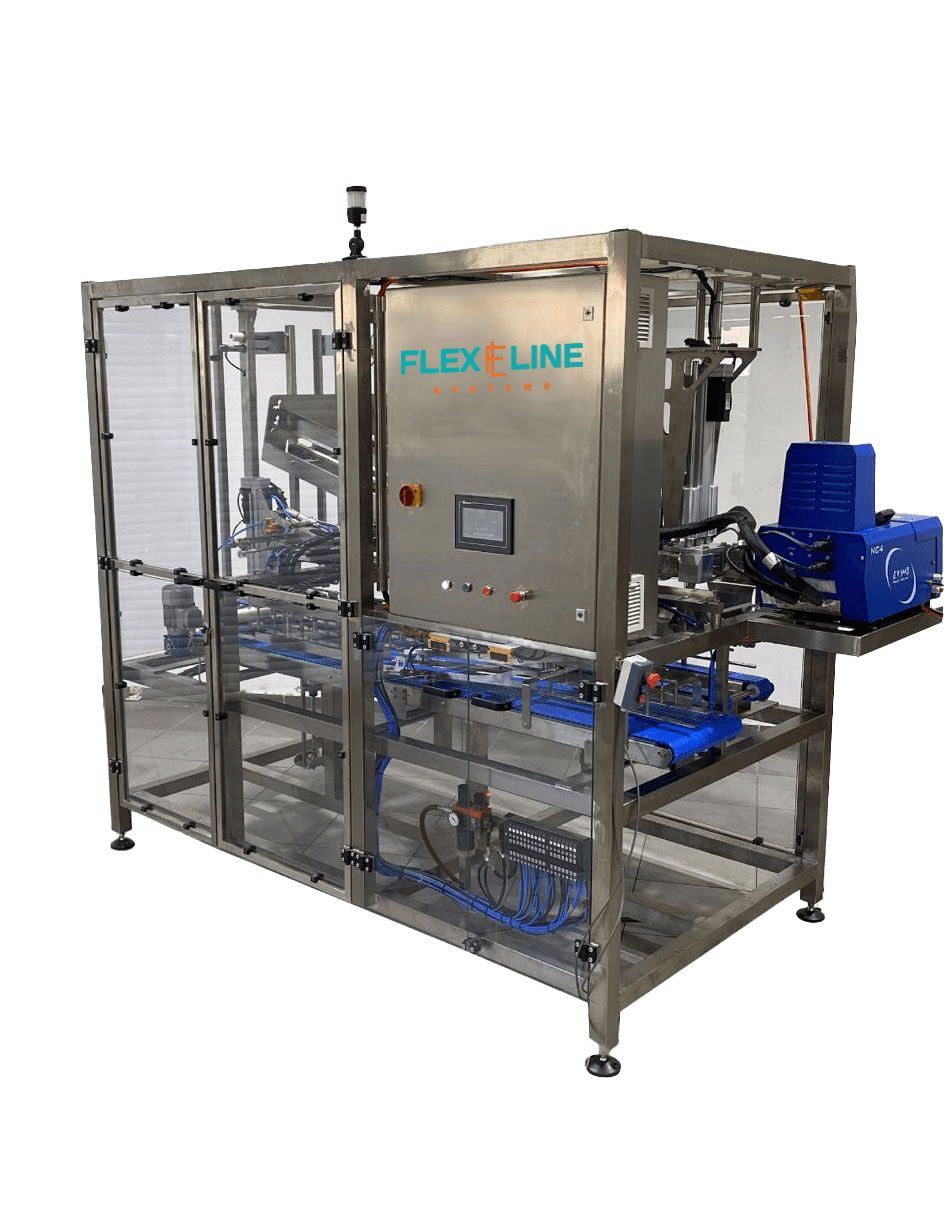

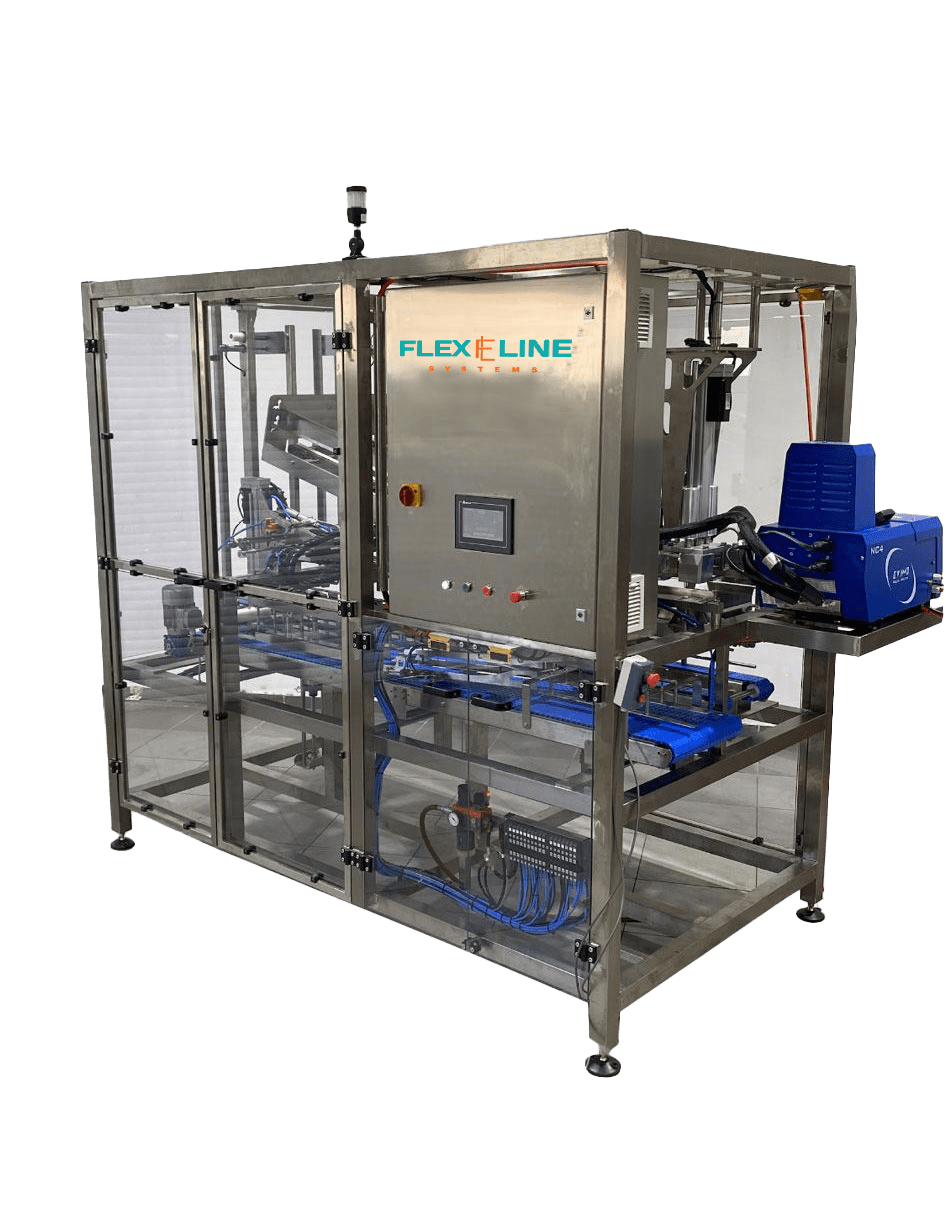

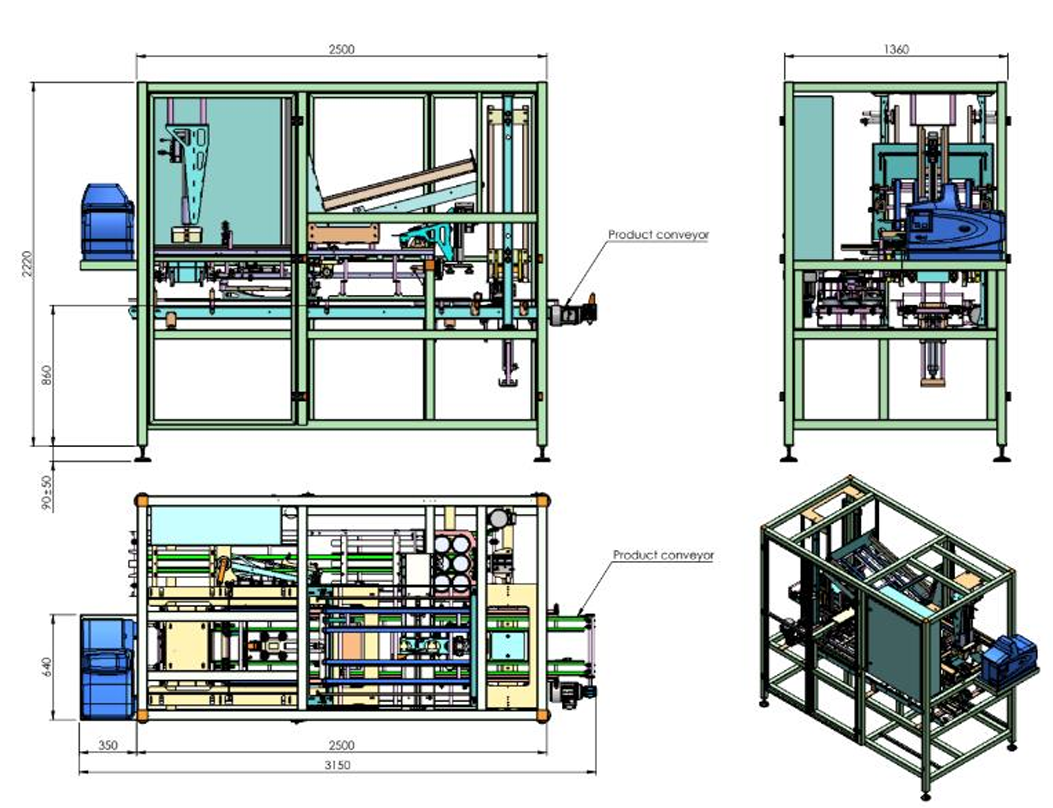

Compact Packaging Machine Designed as an Automated System with Multiple Sequential Modules

Main modules of the machine:

Tray forming station with glue application

- Trays are formed from flat blanks.

- A glue application unit precisely applies adhesive to designated areas of the blank.

- A pressing unit folds and secures the tray until the glue fully sets.

Packaging distribution module

- A conveyor feeds the finished packages in a single line.

- A sorting system divides the packages into groups of six using a flow divider.

Handling manipulator for stacking

- A robotic manipulator with a vacuum or mechanical gripper.

- Places packages into the tray in two layers (6 packages per layer).

- Adjustable parameters allow operation with different package formats.

Stacking station for finished trays

- A conveyor moves filled trays to the stacking module.

- An automatic lifting/lowering system stacks the trays to a specified height.

- A built-in stabilization unit ensures stack stability.

Design features:

- Compactness: Optimal module layout minimizes the machine’s footprint.

- Automation: Programmable manipulators and control sensors minimize manual labor.

- Versatility: Adjustable settings enable compatibility with various tray and package sizes.

Materials and components:

- Frame: Stainless steel (hygienic and wear-resistant).

- High-precision servomotors: For the manipulator and transport units.

- Industrial controllers (PLC): For machine control.