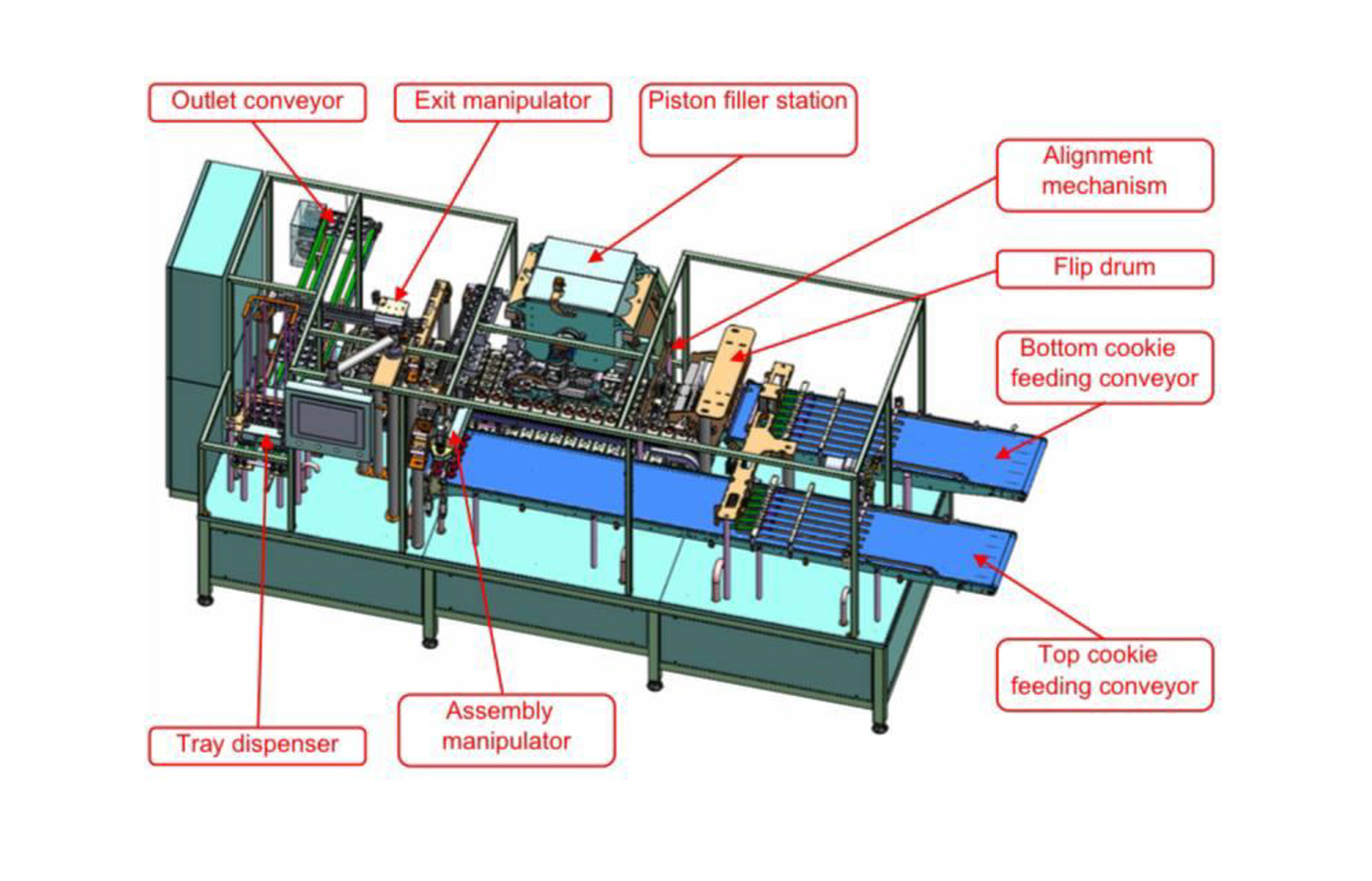

General Purpose:

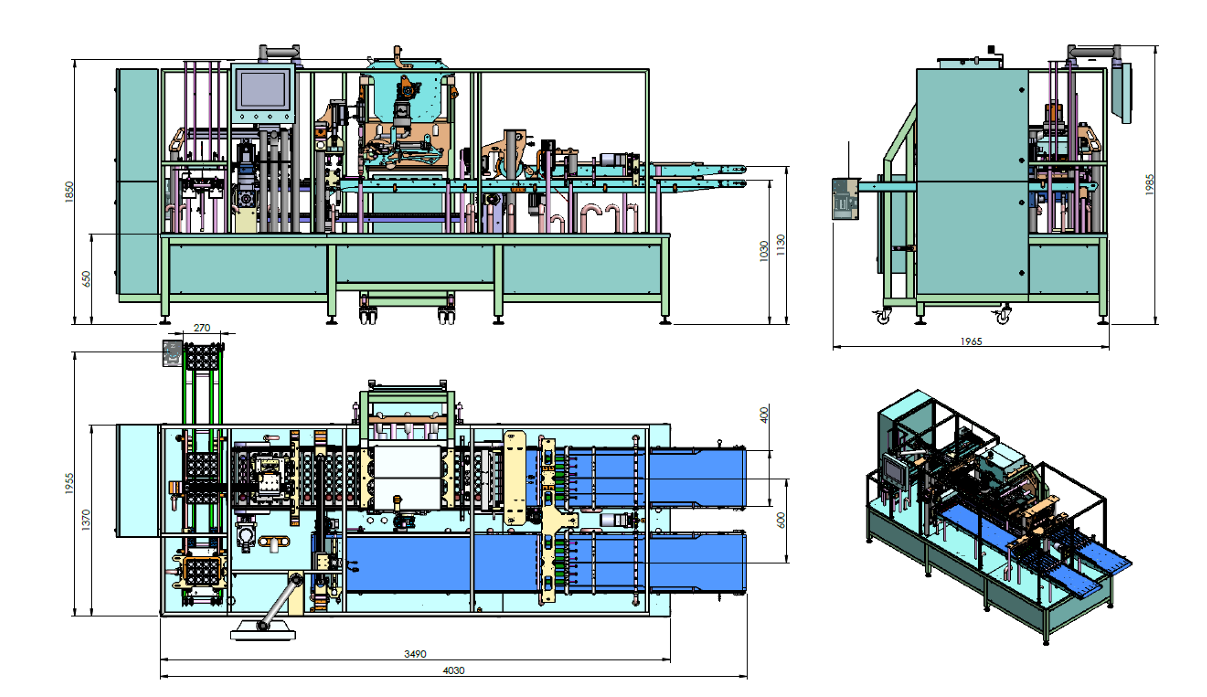

The modern high-performance machine is designed for the automatic assembly of macaroon cookies and other varieties of cookies with filling. The assembly is performed simultaneously on 6 lanes, ensuring a production rate of up to 100 units per minute. The equipment combines high operational precision with gentle product handling, guaranteeing the quality of the final product.

Technical Specifications and Main Components:

1. Bottom Cookie Feeding Conveyor

- Equipped with guides to align cookies into 6 lanes.

- A gate mechanism releases rows of 6 units at a time for transfer to the main conveyor.

2. Flip Drum

- Feeds the bottom cookie upside down onto the main conveyor.

3. Alignment Mechanism

- Precision system for accurate positioning of bottom cookies in the working area.

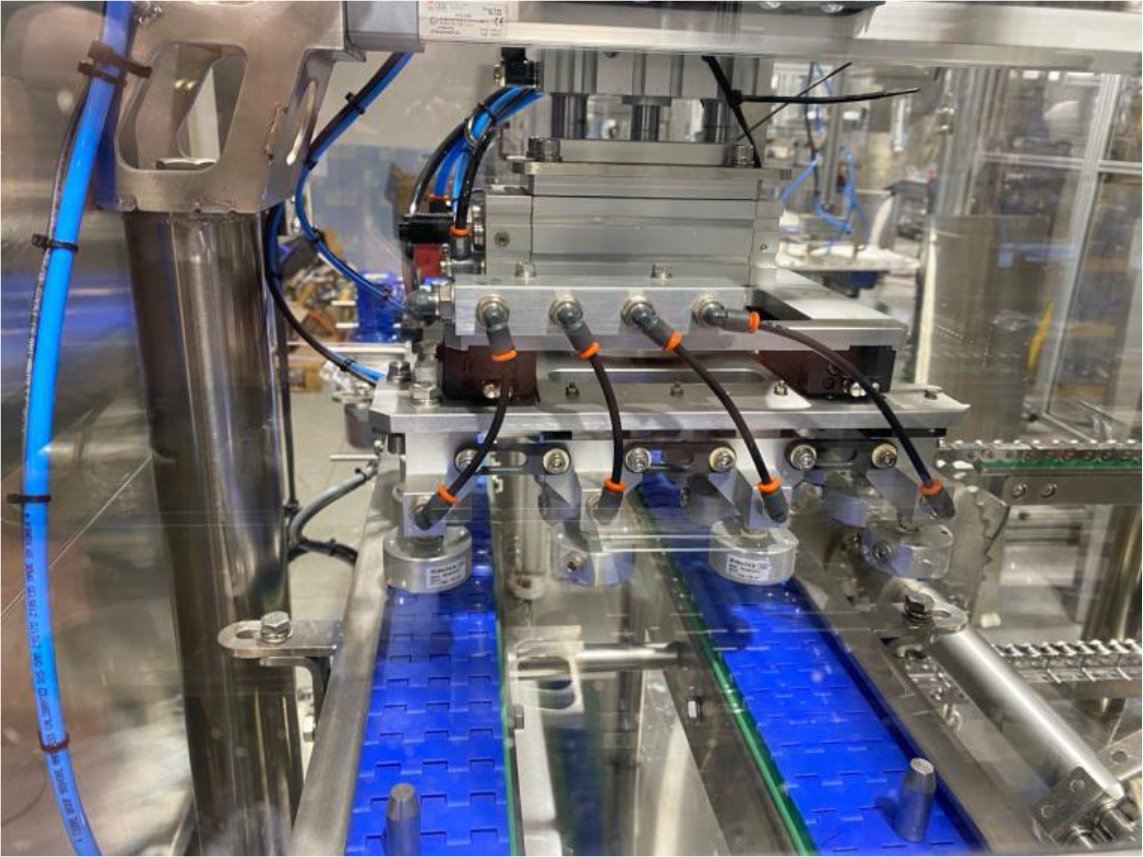

4. Piston Filling Station with 6 Heads

- Includes a 60-liter double-jacket tank to maintain the filling at the required temperature.

- Ensures precise and uniform filling application on each bottom cookie.

5. Top Cookie Feeding Conveyor

- Moving guides align the cookies into 6 lanes, forming a 6×2 array at the end.

- A gate mechanism controls the release of aligned rows of cookies.

6. Assembly Manipulator

- Equipped with contactless grippers for the careful placement of 12 top cookie halves onto the bottom cookies with filling.

7. Exit Manipulator

- Adjustable contactless grippers ensure the simultaneous extraction of 24 completed macaroons from the main conveyor and their placement into trays.

8. Tray Dispenser

- Fully automated system for feeding trays onto the outlet conveyor.

9. Outlet Conveyor

- Transports filled trays with completed products for further packing or transportation.

Key Advantages:

- High Productivity: Up to 100 units per minute.

- Full Automation: Eliminates manual labor at all assembly stages.

- Gentle Product Handling: Contactless grippers prevent damage to delicate items.

- Flexibility: Capable of handling various types of cookies and fillings.

- Ease of Maintenance: Intuitive interface and easy cleaning process.

Applications:

Ideal for industrial-scale confectionery production, delivering high productivity, consistent quality, and minimal product loss.