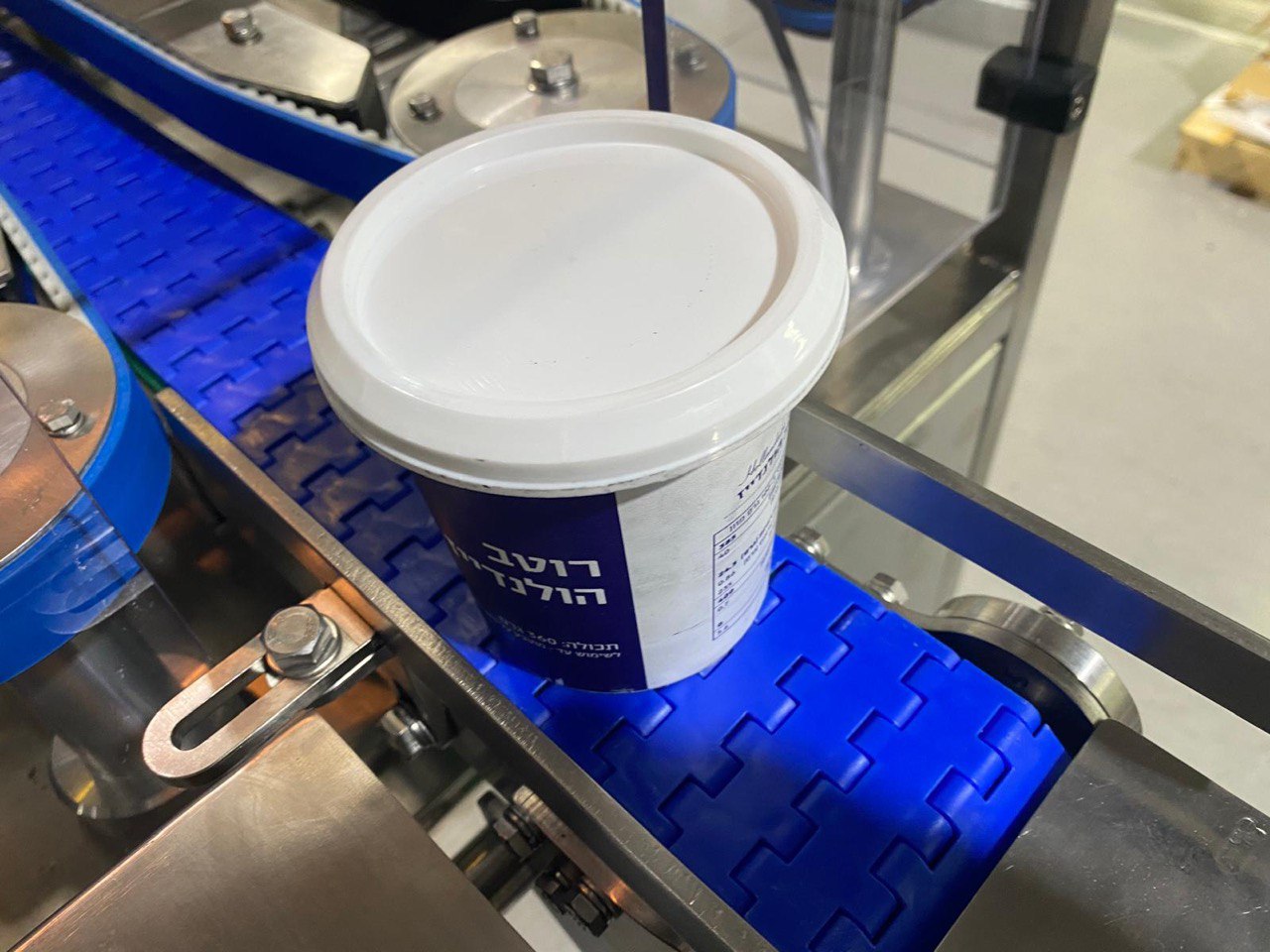

Leading System offers innovative equipment for automatic placement of lids and sealing on plastic cups of various sizes and formats. The machine provides high speed and precision, making it an ideal solution for high-volume production lines.

Key Features

1. Versatility

• Suitable for plastic cups of various sizes and shapes.

2. High Productivity

• Processing Speed: Up to 2,400 cups per hour.

• Continuous operation, eliminating downtime and ensuring stable performance.

3. Secure sealing

• Precise and uniform arrangement of the lid on the cups.

• Advanced fixation and sealing systems ensure secure packaging.

4. Technological Advantages

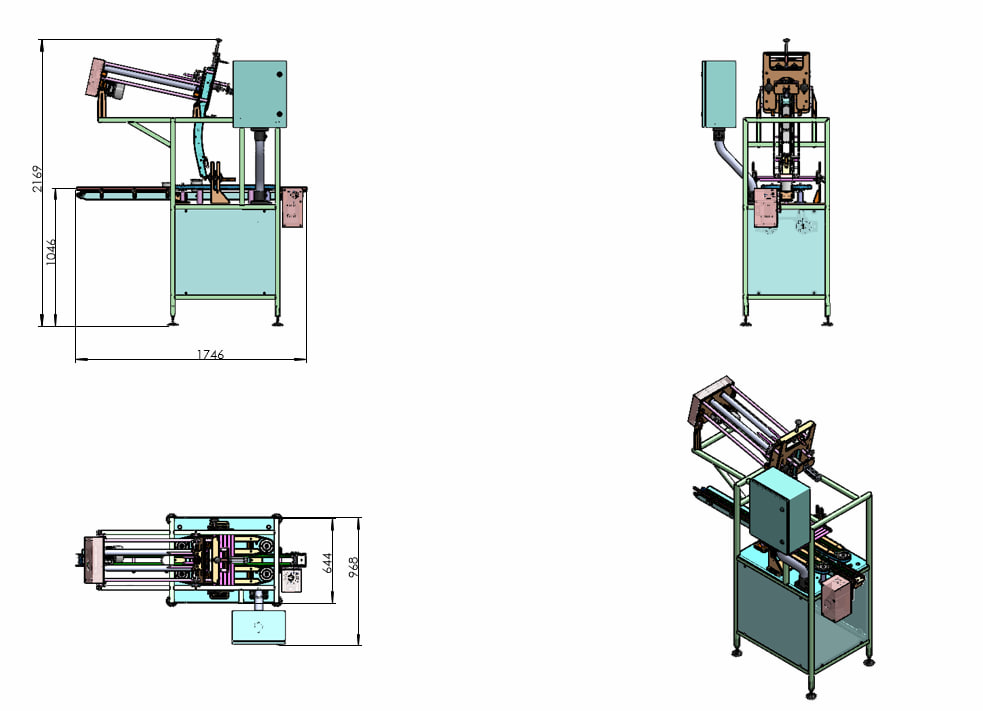

• Conveyor System: Adjustable Speed Cup Conveying System.

• Lid Feeding Unit: Automated synchronized lid dosing with optional orientation.

• Sealing system: securely close the lid using pneumatic technology.

5. Hygiene & Safety

• Stainless steel construction that meets food industry standards.

• Easy to clean and maintain.

Advantages of using the

machine• Efficiency – increases the speed of packaging through automation.

• Versatility – Works with a variety of cup sizes and types.

• Reliability – ensures precise placement of the lid and reduces the number of defects.

• Cost-effective – minimizes manual labor and optimizes production.

Applications

The machine is ideal for packaging dairy, beverages, sauces, and desserts, providing high-quality, durable packaging.

Leading System – taking packaging automation to the next level!