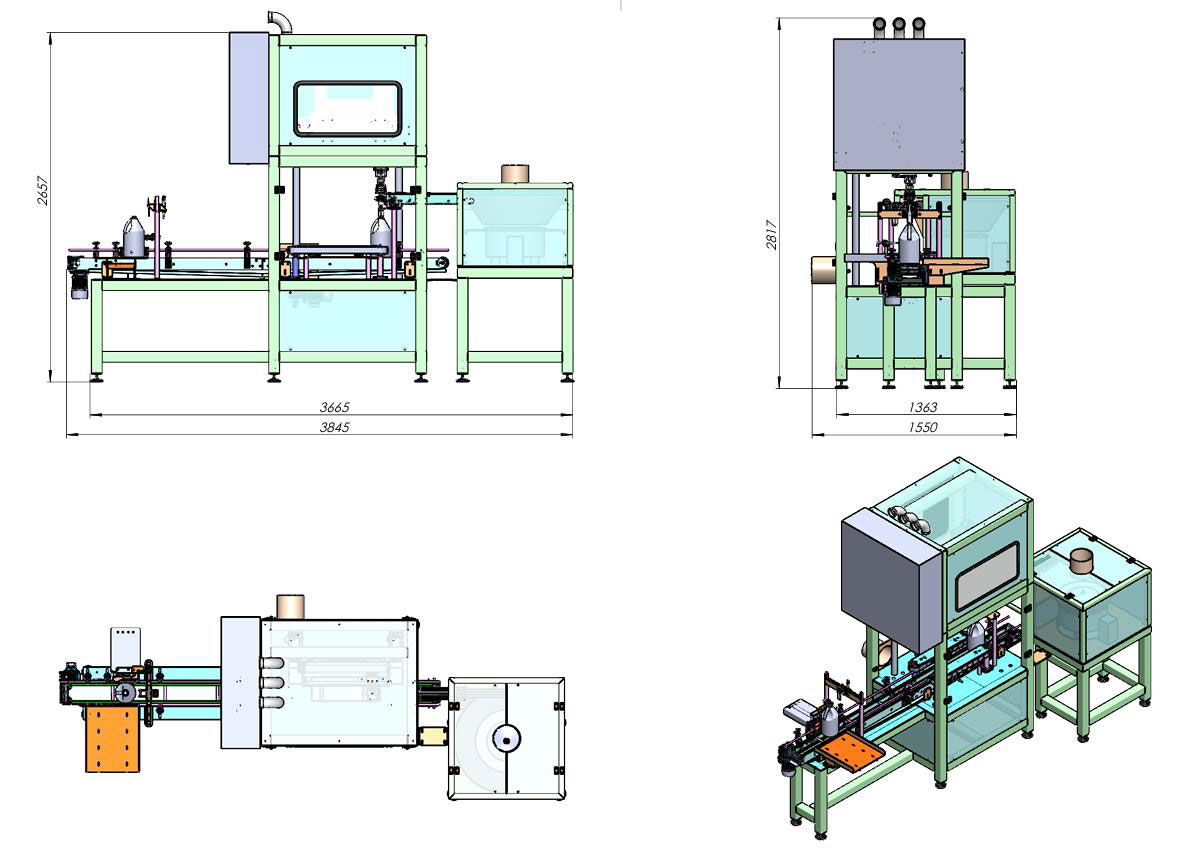

The line is designed for automatic feeding, orientation, screwing of caps onto bottles, and quality control of closure. The system ensures high productivity through synchronized operation of all units without stopping the conveyor.

1. Conveyor System

- Conveyor Type: Belt conveyor equipped with guides for stable bottle movement.

- Speed: Adjustable (up to 50 bottles per minute).

- Detection Sensors:

- Optical sensors detect the presence of bottles on the line.

- The system synchronizes the manipulator’s operation with the bottle movement.

- Materials: Stainless steel resistant to wear and chemical exposure.

2. Cap Feeding and Orientation Module

- Vibratory Bowl Feeder:

- Automatically orients caps into the correct position.

- Capacity is designed for extended operation without frequent refilling.

- Transport System:

- Delivers caps to the gripper via an inclined chute.

- Compatible with caps of various shapes and sizes (adjustable guides).

3. Manipulator with Gripper

- Construction: Robotic manipulator

- Gripper:

- A specialized gripping mechanism with adjustable force for precise handling of caps.

- Ensures the cap is picked, transported, and screwed onto the bottle

- Operating Principle:

- The manipulator tracks bottle movement on the conveyor.

- Screws caps without stopping the conveyor (synchronized motion).

4. Quality Control System

- Key Functions:

- Verifies the closure’s tightness.

- Detects the presence of caps.

- Monitors screwing torque to prevent bottle damage.

- Control Methods:

- Torque sensors integrated into the gripper.

5. Rejection Module

- Functionality:

- Identifies defective bottles (loosely closed caps, missing caps, or defective containers).

- Automatically removes defective bottles from the line.

- Monitors screwing torque to prevent bottle damage.

- Control Methods:

- Torque sensors integrated into the gripper.

6. Control Panel

- Interface: Touchscreen with a user-friendly interface

- Control Functions:

- Adjusting conveyor speed.

- Regulating screwing force.

- Displaying performance statistics and defect reports.

- Warning and troubleshooting diagnostics system.

8. Additional Options

-

- Integrated bottle marking module.

- Cap sterilization module before screwing.

- Integration with enterprise ERP systems.

- Adjustable parameters for handling bottles and caps of different formats.

Advantages of the Automatic Line:

- High Productivity: Continuous process with minimal operator intervention.

- Flexibility: Suitable for a wide range of bottles and caps.

- Quality: Integrated control of tightness and screwing precision.

- Resource Efficiency: Reduces manual labor costs.

- Reliability: Durable materials and components designed for long-term use.